Silica sand applications areas and production process

Silica sand applications areas and production process

Blog Article

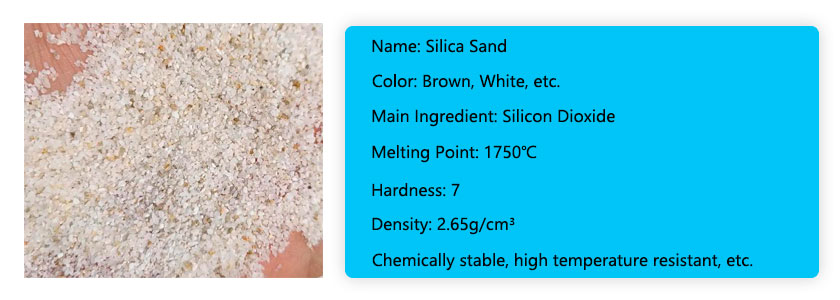

Introduction to silica sand

Silica sand is a non-metallic mineral resource mainly composed of quartz. It is a mineral particle contained in sedimentary rocks formed by weathering, flowing water, sedimentation and biological processes under natural conditions, and after years of geological processes. It is commonly found in beaches, riverbeds, gravel mines and other places.

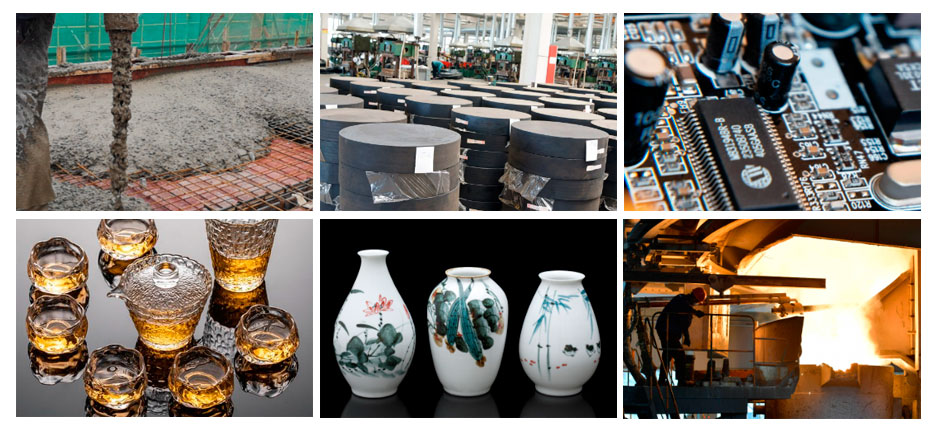

what is silica sand used for?

Since silica sand has the characteristics of high melting point, good chemical stability, uniform particles and high hardness, it is widely used in electronics, construction, glass, chemical industry, ceramics, metallurgy and other fields. It is mainly used to manufacture electronic components, silicon steel, glass, resin, porcelain and so on.

Basic characteristics of silica sand

Silica sand is a kind of silicon dioxide mineral with high hardness, with a melting point of 1750℃, hardness and density of 7 and 2.65 respectively, and is usually brown, white and so on. In addition, it also has the characteristics of corrosion resistance, high temperature resistance, good mechanical properties and chemical stability.

Classification of silica sand

According to the mining and processing methods, it can be divided into: washed sand, artificial silica sand, scrubbing sand, selected sand, etc.

According to the use of silica sand, it can be divided into: artificial silica sand, natural silica sand, selected natural silica sand.

According to the origin, it can be divided into: river alluvial clay quartz sand, lake quartz sand, coastal quartz sand, etc. Among them, coastal quartz sand has the best quality and is often used in high-demand industrial applications.

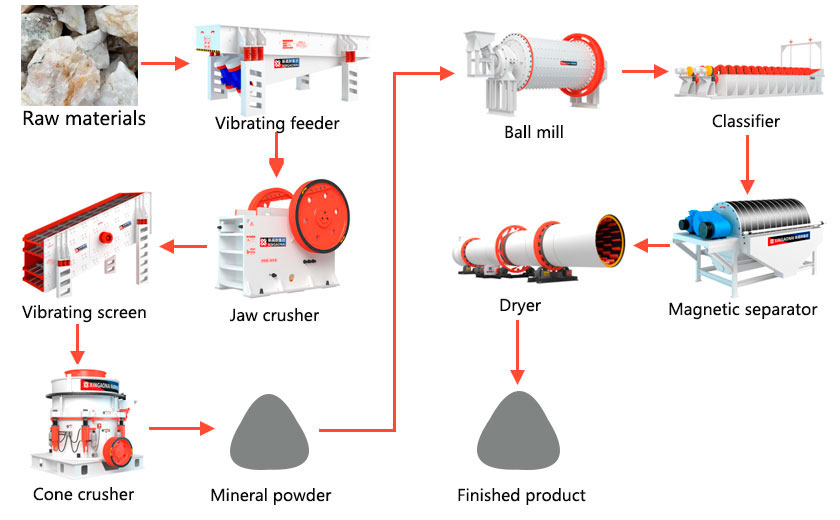

Production process of silica sand

Introduction to the production process: Deep processing of sandstone with high silica content, mainly crushing, grinding and grading, to obtain silicon materials that meet the requirements. Because natural silica sand contains a lot of soil and impurities, in the mineral processing operation, the soil and impurities are graded and treated. If the iron and aluminum content is high, a magnetic separator is required for impurity removal.

Main production equipment: vibrating feeder, jaw crusher, vibrating screen, Cone Crusher, ball mill, classifier, magnetic separator, dryer, etc.

Production process: Large pieces of silicon ore raw materials are evenly fed into the jaw crusher by the vibrating feeder for primary crushing, crushed into smaller particles, and then crushed by the cone crusher for secondary crushing. After crushing to the size required by the ball mill, the ball mill is used for grinding and sand making. Because it contains impurities such as soil, it needs to be removed by a classifier and iron removed by a magnetic separator to improve the purity of silica sand. Finally, it is dehydrated and dried by a dryer and sent to the finished product warehouse.

Silica sand applications

Construction field: cement and concrete without silica sand can improve the stability and durability of buildings.

Chemical field: silica sand is one of the raw materials for producing chemical products such as silicates and silicon compounds. It has heat resistance and stability. It can be used as filler, catalyst, dehydrating agent, etc., and is used to make plastics, rubber, resin, etc.

Electronic field: silica sand has good conductivity and is one of the raw materials for making chips. It is mainly used to make integrated circuits of electronic components.

Glass field: silica sand has high strength and good light transmittance, and is an important raw material for glass manufacturing. It is widely used in the manufacture of glassware, solar panels, LCD screens, etc.

Ceramic industry: Siliceous materials are used to make porcelain embryos from clay mixtures. Adding an appropriate amount of silica sand can improve the plasticity of the product and the strength of the structure under high temperature conditions. It is widely used in the manufacture of vases, porcelain, etc. Metallurgical field: Silica sand is the raw material for manufacturing high-silicon alloys, refractory materials, etc., and plays an important role in steel smelting.

Author:[Xingaonai]

Article Title: Silica sand applications areas and production process

Reprint URL: https://www.xgncrusher.com/Industralnews/Silica-sand-applications-areas-and-production-process.html